GREEN MANUFACTURING, LASER ASSISTS COAL MINING MACHINERY

Plasma Equipment and Laser Cutting

(12/5/2023)

Intelligent Transformation

At present, the demand of coal mining enterprises for high-reliability, intelligent and green coal machinery equipment is further strengthened, which is promoting the transformation of the coal mining machinery and equipment industry towards high-end and intelligent.

Most of the parts of coal mining machinery equipment are medium and thick plates. In the past, large coal machinery enterprises often used imported plasma equipment for cutting. However, plasma cutting has seriously hindered the transformation of coal machinery enterprises.

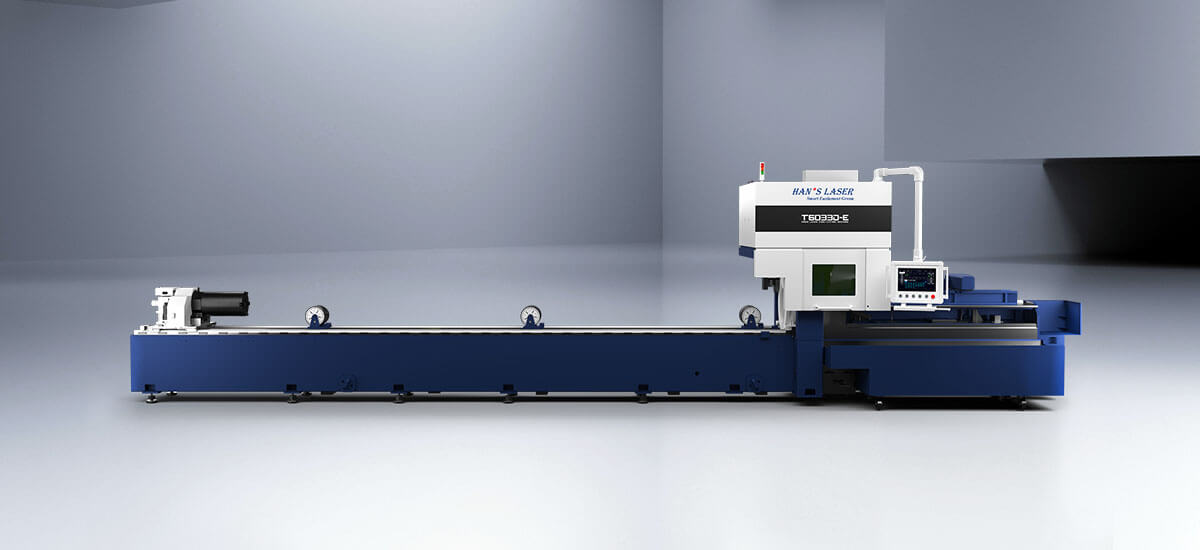

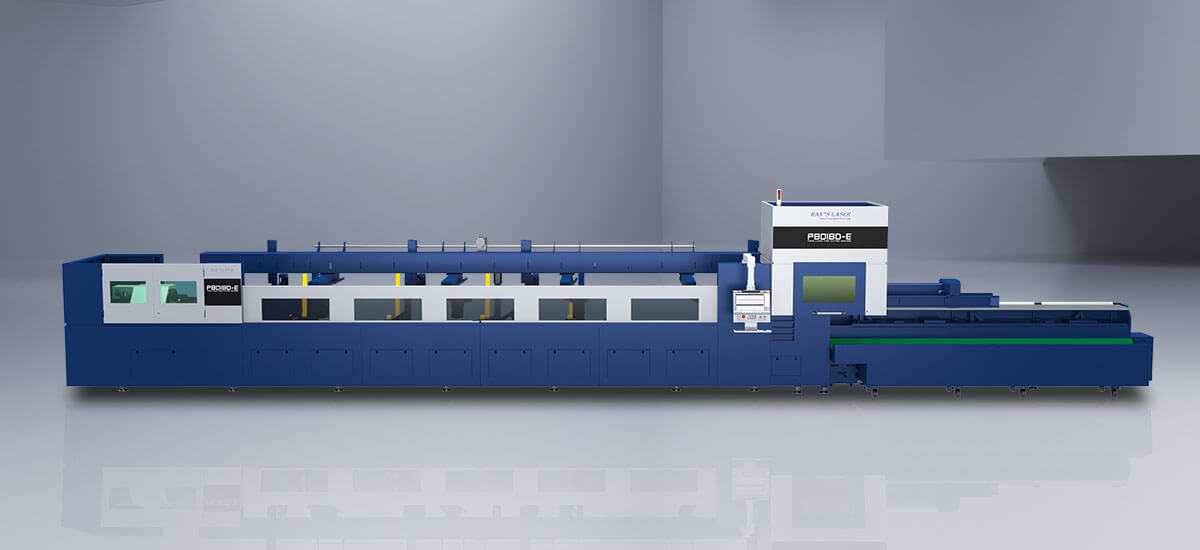

In order to get rid of the constraints, the well-known coal machinery group introduced the laser cutting machine of Han’s Laser Smart Equipment Group.

Laser Cutting vs Plasma Cutting

(Comparison of advantages)

Cutting Quality:

Plasma equipment is suitable for cutting medium and thick plates of 20-40mm. Laser cutting machines can achieve high-quality cutting of thin and medium plates, and the cutting range is wider.

Gap contrast:

Taper comparison:

Precision:

Cost comparison

By actual comparison, the energy consumption of laser cutting is only 40%-50% of that of plasma cutting

Material costs

When cutting the same plate, the utilization rate of plasma cutting materials is 78%, and the utilization rate of laser cutting materials can reach 92.67%.

Environmental comparison

Efficiency comparison

In terms of processing efficiency, cutting 16-30mm high-strength steel plates, 15kW and 20kW laser cutting machines have obvious advantages over plasma cutting.

Comparison of cutting speeds between imported plasma equipment and Han’s 20kW laser cutting machine for cutting high-strength steel with different thicknesses (m/min)

In addition, plasma equipment cannot cut small holes, and manual secondary processing is required after cutting, which is inefficient. Laser cutting machines complete small hole processing at one time, which greatly improves efficiency.

For cutting medium-thick and high-strength steel plates, Han’s Wanwa laser cutting machine has faster speed, better precision, and smoother cross-section, helping the high-quality development of industries such as coal mining machinery and equipment!